ENVIRONMENTAL RESTORATION program

The Environmental Restoration Program is a Department of the Navy (DoN) initiative to identify, investigate and clean up former waste disposal sites on military property. The Program’s objectives are to reduce the risk to human health and the environment from past waste disposal operations and hazardous material spills in a cost-effective manner. Click on the following link if you would like more information on the Navy's Environmental Restoration Program.

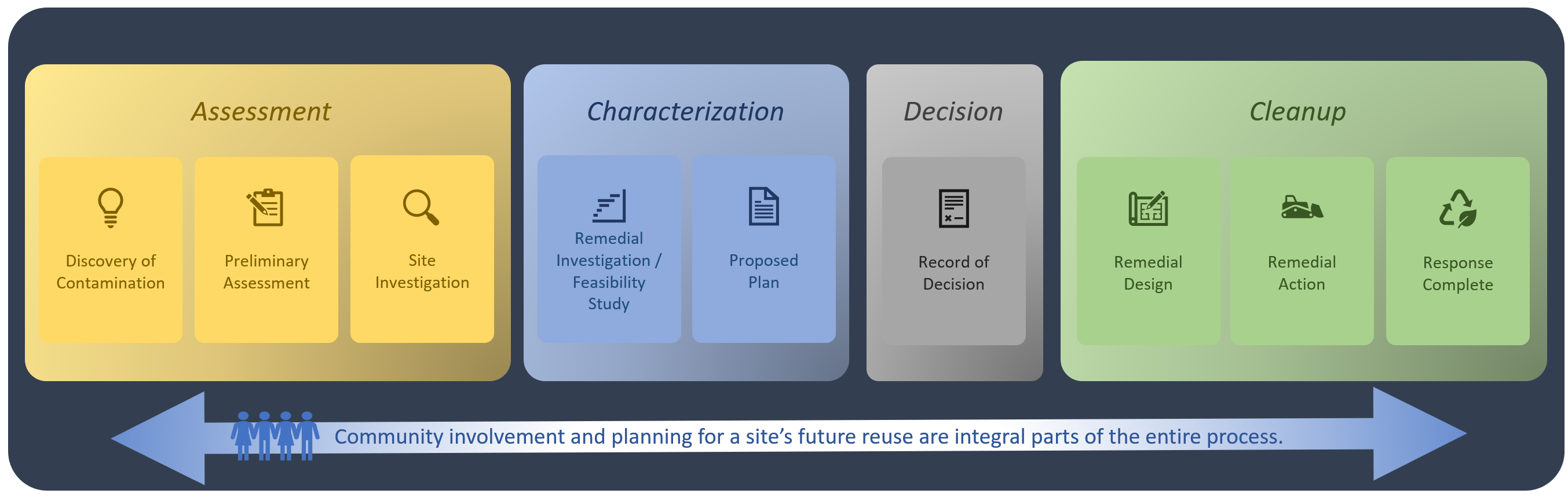

THE ENVIRONMENTAL RESTORATION PROCESS

Environmental restoration (also known as ecological restoration) is the process of recovering an impaired, damaged, and/or destroyed ecosystem. Ecosystems that experience impairment or damage include oceans, lakes, streams, fields, forests, wetlands, soils, fisheries, and coastlines.

In 1976, Congress passed the Resource Conservation and Recovery Act (RCRA) designed to manage disposal of wastes which were being generated. In 1980, Congress passed the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund, requiring identification, investigation and cleanup of sites contaminated by past releases of hazardous substances. Congress amended CERCLA in 1986 to create the Defense Environmental Restoration Program which is managed by the Office of the Deputy Under-Secretary of Defense (Installations and Environment). The Defense Environmental Restoration Program cleans up hazardous substances, pollutants, contaminants and military munitions remaining from past activities at military installations and formerly used defense sites. There are two programs to accomplish cleanup goals. The Installation Restoration Program primarily addresses sites impacted by hazardous substances, pollutants, or contaminants that pose environmental health and safety risks. The Military Munitions Response Program responds to unexploded ordnance and military munitions waste at areas other than operational ranges.

RISK ASSESSMENT

As part of the environmental cleanup process, risk assessments are conducted. Risk assessments characterize the nature and magnitude of potential risks from exposure to chemical contaminants released into the environment to the health of humans (e.g., residents, workers, recreational visitors, etc.) via the Human Health Risk Assessment process and to ecological receptors (e.g., birds, fish, mammals, etc.) via the Ecological Risk Assessment process.

An Ecological Risk Assessment is used to evaluate ecological risks associated with the presence of contaminants in soil, surface water, sediment, and groundwater.

A Human Health Risk Assessment is conducted to evaluate the potential human health risks associated with the presence of contaminants in surface and subsurface soil, surface water, sediment, and groundwater at a site. The human health risk assessment characterizes current and potential future human health risks at a site if no additional remediation were to be implemented.

EMERGING CONTAMINANTS

The DoD defines an Emerging Contaminant (EC) as “a chemical or material that is characterized by a perceived or real threat to human health or the environment with no published health standard, or an evolving standard.” These contaminants may be difficult to assess because many have insufficient or limited health and science data available. Since the standards, toxicity values, and/or science continually evolve, so does the list of chemicals currently considered ECs.

US NAVY GUIDANCE

ADMINISTRATIVE RECORD FILE (ARF)

The ARF is a collection of documents compiled by the Department of the Navy to document military installation Environmental Restoration Program environmental response actions. Documents are continuously being added to installation ARFs.

The ARF serves two purposes:

-

It provides access to site-specific information so that the public may make informed comments to the US Navy on the selection of response actions.

-

If the adequacy of a response decision is challenged in court, the judicial review of that decision will be based on the documents in the ARF.

Click the map below to access the installation and corresponding administrative record files.

DOCUMENTS AVAILABLE FOR PUBLIC COMMENT

Throughout an Environmental Restoration cleanup, some documents are made available for public review and comment. Public notice of a document’s availability is announced through a variety of media outlets. The public is encouraged to use formal comment periods to submit comments on proposed cleanup choices. The Navy welcomes comments at any time on installation Environmental Restoration cleanup work.

Some installations have Administrative Record Files and other documents available at community outreach centers; other installations use online public web pages for the Administrative Record File and to make documents available for public comment. Directions for making comments are provided. Consult individual installation web pages for point of contact information.