Collapse All Expand All

NFA Site Locations

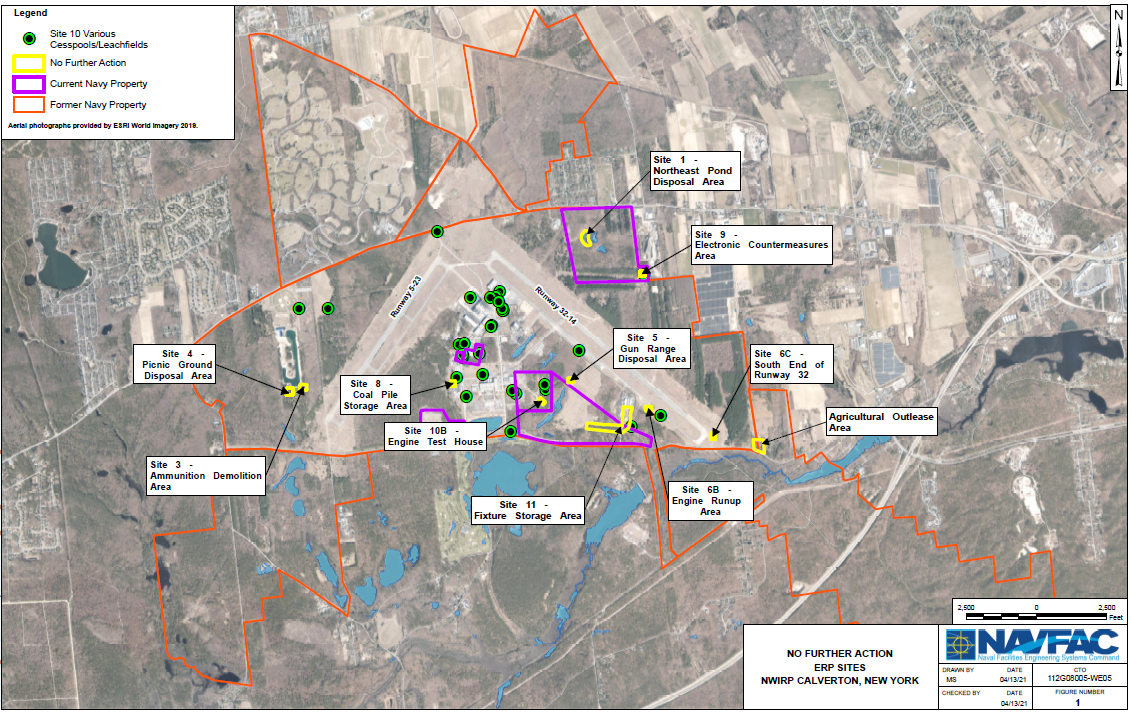

NFA Site LocationsClick on a site label for more information.

Site 1 - Northeast Pond Disposal Area

Site 1 - Northeast Pond Disposal Area

Site Description: Site 1- Northeast Pond Disposal Area was located approximately 1,000 feet south of Middle County Road (NY Route 25) and 0.95 miles east of NWIRP-Calverton’s north gate. Site 1 consisted of a relatively flat borrow and disposal area that encompassed approximately two acres.

Site History: Site 1 was intermittently used as a landfill before Navy acquisition of land in 1947. The Navy continued landfilling at Site 1 until 1984 at which time it was covered with soil (approximately 2.3 acres). The landfill was primarily used for the disposal of demolition debris such as concrete, brick, wood, and other construction materials, one drum containing petroleum and chlorinated solvents was found during the Remedial Investigation. Site 1 contains the state endangered tiger salamander and is an archeologically significant and a wetland.

Environmental Investigations/Interim Action: The 1986 IAS was conducted and recommended a Confirmation Study for Site 1. An SI was conducted in 1992 and because of VOC and metals contamination in soils, sediment and surface water, the SI recommended an RI/RFI.

An HHRA was conducted during the 1997 RFI. The HHRA concluded that, the conditions posed an insignificant threat to human receptors engaged in routine occupational and recreational activities at the site.

An Ecological Risk Assessment (ERA) conducted for the 1997 RFI identified potential chemicals of concern in surface soil, surface water and sediment at Site 1. Toluene, phenolics, pesticides, PCBs, cadmium, lead, nickel, and silver in sediment could have represented potential ecological risk. Chemicals detected in surface water that may have potentially caused risk to ecological receptors included 4,4’- dichloro diphenyldichloroethane (DDD), aluminum, cadmium, and iron. For surface soil on the landfill cover, chromium and PCBs represented a potential ecological risk.

A 2002 Phase 2 RI summarized the results of previous testing and a Focused FS for Site 1 was prepared. A 2002 Record of Decision presented the selected Remedial Action for OU 1 - soils and sediment at Site 1. The selected remedy in this RODconsisted of excavating all landfill waste materials, contaminated soil, and contaminated sediment with subsequent off-site disposal. Short-term groundwater monitoring would be conducted to determine the impacts, if any, that excavation of the landfill would have had on groundwater quality and whether groundwater use restrictions were necessary. A 2004 Construction Closeout Report documented field activities to fulfill the remedy selected by the ROD.

In 2006, a SOB for Major Permit Modification-No further action decision was submitted to remove Site 1 from the permit. Parcel D included Site 1-Northeast Pond Disposal Area and Site 9-ECM Area was transferred to the Town of Riverhead in 2007.

Site 3 - Ammunition Demolition Area

Site 3 - Ammunition Demolition Area

Site Description: Site 3-Ammunition Demolition Area was first identified in the 1986 IAS. Site 3 was located to the northwest of the activity's runways and industrial areas.

Site History: Site 3 was the site of controlled demolition of excess or off-specification ammunition (mostly aircraft cannon rounds) from 1957 to 1965. Reportedly, personnel performed thorough post-operation clean-up and disposal after each demolition exercise. The practice of ammunition disposal in this manner ended in 1985, when personnel decided to construct a controlled facility.

Environmental Investigations: According to the 1986 IAS, personnel destroyed ammunition by setting fire to 5 to 10 gallons of various types of waste fuel (JP-4, JP-5) in a 55-gallon drum placed in an unlined pit. The ammunition was released into the fire. Personnel removed remaining shell casings and projectiles after each exercise. In 1985, personnel destroyed an estimated 1,700 rounds of ammunition and signal flares at the site. Reportedly, this quantity is considered representative of the quantity destroyed each year from 1957 to 1985.

The quantities of ammunition destroyed at Site 3 were comparatively limited, and thorough post-operation clean-ups were reportedly performed. Ammunition was not considered to be a contaminant of concern at this site. POL's used to incinerate the ammunition were also used in small quantities, and were reportedly incinerated during the exercises. Therefore, Site 3, Ammunition Disposal Area was not recommended for a Confirmation Study.

Site 4 - Picnic Grounds Disposal Area

Site 4 - Picnic Grounds Disposal Area

Site Description: Site 4 was first identified in the 1986 IAS. Site 4 was located approximately 500 feet west of Site 3, Ammunition Demolition Area. It consisted of a single trench-type landfill, approximately 60 feet long by 40 feet wide.

Site History: Site 4 was active from 1947 (prior to Navy acquisition) until the early 1980s. According to Navy and Grumman representatives, the area was not an authorized, active disposal site. Personnel could provide no information regarding past disposal operations at this site.

Environmental Investigations: According to the 1986 IAS, the estimated maximum volume of material disposed at Site 4 was 500 cubic yardsthat consisted of picnic tables, metal fabrications, old fences, demolition debris, foam, plastic, carpeting, and plywood. As stated, no shops or personnel at the activity could provide information regarding past or current disposal operations at this site. Records did not exist to document operations at this site. In light of the long operational life of the disposal area, the possibility that hazardous wastes may have been disposed of at the site during a period when awareness of the dangers of hazardous waste was lower, and the immediate proximity of the Upper Glacial Aquifer, Site 4 was recommended for a Confirmation Study.

A Site Investigation was conducted in 1992 to obtain environmental information in order to eliminate from further investigation those sites that posed no definable threat to the environment or to public health. Based on the absence of significant contamination in site soils, no additional investigation at Site 4 was recommended.

Site 5 - 1950s Gun Range Ammunition Disposal Area

Site 5 - 1950s Gun Range Ammunition Disposal Area

Site Description: Site 5-1950s Gun Range Ammunition Disposal Area was first identified in the 1986 IAS. Site 5 was located approximately 500 feet northwest of the Radio Noise Check Area and the Engine Run-Up Area.

Site History: Site 5 was the first area at NWIRP Calverton used for the testing of aircraft cannons. In the early 1950s guns and airborne cannons were tested before they were installed in aircraft. Ammunition that failed to fire during testing may have been disposed of in an intermittent stream and swamp area. Reportedly, the range operated for 1 to 1-1/2 years, until about 1953. In 1957, operations were transferred to the Gun Butt Facility. Presently, no buildings, earthen ramparts, or other structures at the site suggest the range's existence.

>Environmental Investigations: In January and May of 1986, the original gun firing test site was scanned with a metal detector. No ammunition items were detected. Therefore, Site 5 was not recommended for a Confirmation Study.

Site 6B - Engine Run-Up Area/6C - South End of Runway

Site 6B - Engine Run-Up Area/6C - South End of Runway

Site Description: Site 6B-Engine Run-up Area and Site 6C-South End of Runway 32-14 were identified in the 1986 IAS due to fuel spills. Site 6B and 6C are located 4,500 feet and 6,500 feet, respectively, east-southeast of the fuel calibration pad at Site 6A.

Site 6B is a 500- by 100-foot concrete area adjacent to the taxiway and is surrounded by a metal blast fence on the three remaining sides. The area beyond the blast fence is open and grass covered. Site 6C is at the southwest corner of the runway, at the end of the concrete taxiway. Aircraft turned in this area to stage for takeoff. The site is located approximately 200 feet north of River Road and 8,200 feet east of the south gate.

Site History: The primary environmental concern at Sites 6B/6C was the spillage of aircraft fuels. According to the 1986 IAS, as many as 230 gallons of fuel are recorded to have been spilled in these areas. The majority of the spillage was expected to be concentrated in the areas surrounding Site 6A.

Environmental Investigations: An SI was conducted in 1992 to obtain environmental information in order to eliminate from further investigation those sites that posed no definable threat to the environment or to public health. Soils and groundwater were sampled and the analysis did not indicate the presence of significant contamination in these areas. As a result, no additional investigation was recommended at Sites 6B and 6C.

Site 8 - Coal Pile Storage Area

Site 8 - Coal Pile Storage Area

Site Description: Site 8 is behind the Steam Plant in the south central portion of the NWlRP Calverton.

Site History: Site 8 was used for the bulk storage of coal for the onsite steam plant. The coal pile storage area was investigated because of reports that solvents were placed on the coal, The solvents may have passed through the coal and entered the underlying soils and groundwater in the area. The coal pile was removed in the 1980s.

Environmental Investigations: During an initial reconnaissance of the area in October 1992, it was observed that precipitation runoff from the coal pile enters a small marshy area north of the coal pile. This marsh is near production wells for the facility. Two of these wells (Production Wells 2 and 3) were found to be contaminated with low levels of solvents.

Preliminary testing of the site in 1994 identified the potential for hydrocarbon (fuels/oils) contamination may to be present in the soils and groundwater. As a result, a petroleum hydrocarbons and a VOC soil and groundwater investigation was performed in this area to determine if contamination was present.

This investigation was conducted as part of the 1997 RFA Addendum and concluded that additional investigations or remedial actions were not required.

Site 9 - Electronic Counter Measures (ECM) Area

Site 9 - Electronic Counter Measures (ECM) Area

Site Description: Site 9 is located in the northeast corner of the NWlRP Calverton. General site features included the ECM building (Building 07-39), an old debris disposal area located approximately 600 feet to the south, and two depressions located to the east and to the southeast. Construction debris and miscellaneous equipment were visible in and around the disposal area and throughout the southeast depression.

Site History: Site 9 was a test facility for Electronic Counter Measure equipment. The ECM area was investigated because volatile organics were detected in a County Study conducted northeast of the property boundary fence line (and potentially hydraulically down gradient) of the ECM area. In the mid-1990s, the buildings and site structures were removed.

Environmental Investigations: Based on the reconnaissance of the ECM area in October 1992, there was visual evidence that construction debris was disposed near the area. Historic photographs of the facility indicated disturbances of the soils in the area during the 1960s and 1970s. Also, solvents (volatile organics) were used in the laboratory at the site. The disposal of other materials in this area could not be ruled out.

A temporary monitoring well program was recommended to confirm the absence of solvents at Site 9. The 1997 RFA Addendum concluded that the nature and extent of offsite TCA contamination needed to be defined. Based on the Phase 2 Extended SI findings conducted in 2000, no further action was recommended for the site.

Site 10 - Cesspool Leach field Areas

Site 10 - Cesspool Leach field Areas

Site Description: Site 10 – Cesspool Leach Field Areas were a series of leaching pools located throughout the facility to dispose of domestic waste. Each area was generally associated with buildings and structures and was installed with the facility.

Site History: The cesspools/leach fields at the facility were used for sanitary wastes. Several cesspools/leach field areas were investigated because of the potential for industrial wastes to have been discharged to them.

Environmental Investigations: Because of the large number of cesspools/leach fields at the facility, and the consideration that some areas were used only for sanitary wastes (no industrial-type activity in that area), a preliminary screening of potentially contaminated cesspools/leach fields was conducted during the preparation of 1994 RFA Work Plan. This screening reduced the number of areas to be investigated from 22 to 8.

Based on the investigation at 8 sites, Building 06-11 (Site 10A) - Jet Fuel Systems Lab and Building 06-18 - Engine Test House (Site 10B) were potentially contaminated with fuel and/or oil related products. An investigation of soils and groundwater was warranted to define the extent of this potential contamination. These investigations are discussed with the relevant sites.

Site 10B - Engine Test House

Site 10B - Engine Test House

Site Description: Site 10B – Engine Test House is located 1,000 feet south of the Old Fuel Calibration Area, in the south central portion of the facility. Prior to a 2008 Remedial Action, this area consisted of a building, surrounding concrete pad, sparse woods, and open grassy area. A drainage swale and culvert from the Old Fuel Calibration Area runs adjacent to and hydraulically up-gradient of the Engine Test House.

Site History: Testing of aircraft engine systems occurred from the late 1950s to 1996. Minor maintenance and repairs to engine systems were also conducted at the site. In addition, underground storage tanks, including those for jet fuel and waste oil were present. An electric polychlorinated biphenyl (PCB)-containing transformer was also located on the site.

VOC-impacted groundwater originates at Site 6A – Former Fuel Calibration Area flows under Site 10B, and extends off property to the southeast. Investigations have been conducted at Site 10B to evaluate the extent to which site media (soil and groundwater) were impacted from historical operations.

Environmental Investigations/Interim Actions: This area was initially evaluated as part of the 1995 RFA cesspool/leach field investigation. Subsequent testing during the 1997 RFA Addendum found that the cesspool at this site was not a source of environmental contamination. However, during this testing, fuel-type contamination was found in the area of an UST removed in the mid-1990s. Based on an interview with Northrop Grumman, approximately 80 cubic yards of fuel-contaminated soils were excavated during the removal of the UST.

The 1998, the Phase 2 RFI concluded that a relatively small area (approximately 4,800 square feet) of fuel-type BTEX contaminated groundwater was present down gradient of the former UST. Chlorinated VOC contaminated groundwater was also present east of the Engine Test House, most of which was attributed to contamination was Site 6A – Old Fuel Calibration Area via the drainage swale and culvert and groundwater flow.

In 2006, a FS/CMS for Sites 6A, 10B, and the On-site Southern Area was developed and recommended Remedial Action alternatives for soil and groundwater at these sites. A 2007 SOB recommended excavation and off-site treatment and disposal of contaminated soil.

In 2009, the Engine Test House, Fuel Pump House, and underlying petroleum contaminated soil were excavated and disposed off site. Approximately 3,540 cubic yards of soil was excavated and approximately 1,600 pounds of calcium oxyhydroxide were applied at the bottom of the excavation. Disturbed areas were re-vegetated in 2009. In 2010, the remedial action at Site 10B was completed with the removal of a transformer pad and PCB-contaminated soil.

In 2012, the Operable Unit 3 (OU3) ROD was signed and the selected remedy for the Site 10B groundwater was monitoring and LUCs. In 2017, the last round of sampling at Site 10B was conducted to support a Remedial Action Completion Report (RACR). Results indicated that VOCs were below Cleanup Levels.

In 2018, a RACR memorialized the completion of construction of the remedy, allowing for unlimited use and unrestricted exposure.

Site 11 - Fixture Storage Area

Site 11 - Fixture Storage Area

Site Description: Site 11 – Fixture Storage Area is located in the south central portion of NWIRP Calverton.

Site History: Site 11 was used for the storage of miscellaneous portable structures used for assembling aircraft. Site 11 was investigated because historical aerial photographs of the site indicated that material of unknown origin was used to fill in depressions.

Environmental Investigations: This site was evaluated during the 1995 RFA. The low concentrations of solvents at the site were found; however, based on the concentrations detected relative to state guidelines, no additional action was recommended for this site.

Site Description: The Agricultural Outlease Parcel covered an area of 5.77 acres located within the Southeast Buffer Zone which is east of the facility and north of River Road. The subject property was part of a 44.7-acre parcel of land that the Navy had leased to a local farmer until 1996. The parcel consisted of agricultural land plus a cluster of agricultural buildings.

Site History: The Navy transferred most of Zone II, including most of the formerly out-leased agricultural land east of the fenced area to the NYSDEC in 1997 for conservation and public recreation. However, the Navy had identified several areas within the cluster of agricultural buildings as requiring environmental investigation. The Navy, therefore, retained the cluster of agricultural buildings and property (Agricultural Outlease Parcel) to investigated and if necessary conduct an environmental cleanup. The buildings included an abandoned farm house, storage sheds, and garages. Potentially hazardous materials stored in the buildings included pesticides, fertilizer, lead-acid batteries, and miscellaneous flammable or toxic liquids. Two USTs and an AST were also located at the site.

Environmental Investigations/Interim Actions: In 1999, Agricultural Outlease area buildings were dismantled and demolished and all asbestos containing material and lead-based paint were removed from each structure prior to demolition. Approximately 22 tons of asbestos-containing materials (ACM) and lead based paint (LBP) were removed from the buildings. Two, 500-gallon, steel USTs associated with Building 258 (main residence building) were also excavated from the site during demolition activities. In October 1999, 32 containers of hazardous materials were removed from the site. By the end of November 2001, all buildings, waste, storage tanks, and contaminated soil were removed from the area.

A 2001 soil investigation identified soil beneath the concrete slabs for Buildings 260, 265, and 270 contained pesticide concentrations greater than NYSDEC clean-up objectives. However, because the contaminated areas were relatively small, the Navy subsequently decided to conduct a removal action to remove the contaminated soils.

In 2002, the Navy prepared a Construction Completion Report documenting the activities that took place during the removal of pesticide-contaminated soils as well as the results of the confirmation sampling.

In 2005, the Agricultural Outlease Area was transferred to NYSDEC

Back To Top