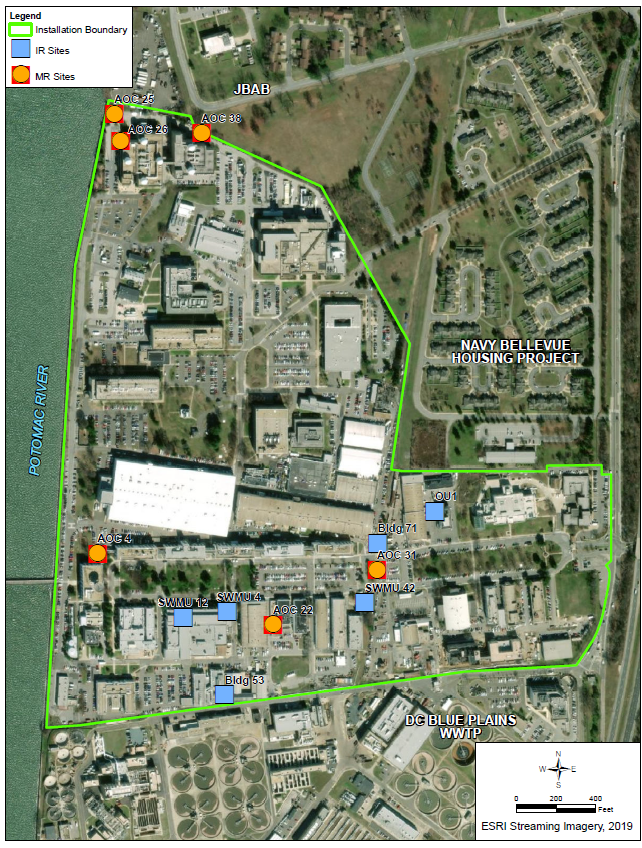

The Navy’s Environmental Restoration Program consists of two programs:

The Installation Restoration Program addresses releases of hazardous substances, pollutants, or contaminants that may pose risks to human health or the environment.

The Munitions Response Program addresses environmental health and safety hazards from unexploded ordnance, discarded military munitions, munitions constituents, and materials of explosive concern.

Active Installation Restoration Program Sites

SWMU 4: Building 2A Former Oil House

SWMU 4 was a former oil house and underground storage tank (UST) located near the northeast corner of Building 2. The oil house was reportedly a cinder block storage shed attached to the east wall of Building 2 with a concrete floor. It was used to store transformer oils, lubricants, and solid wastes. The UST was located beneath the concrete slab floor of the oil house and was used to store waste oil. The tank held 275 gallons and the tank bottom was reported to be between 5 to 8 feet below the ground.

The UST was reportedly installed in the 1940s and was used to store oil from the 1950s to 1975. The UST and associated impacted soil was removed in 1993, and the oil house was demolished in 1994.

SWMU 4 was investigated during the Phase II Facility Assessment, including an assessment for vapor intrusion, which can occur when contaminated vapors move through subsurface soils into the air above, typically into buildings. The Phase II Facility Assessment Report noted that site risks associated with the current and reasonable future exposure scenarios (current industrial worker and potential future construction worker) were within the acceptable risk management range.

Currently, groundwater at SWMU 4 is being investigated as part of the RCRA Facility Investigation.

SWMU 12: Building 2 Former Plating Shop

SWMU 12 consisted of four rooms containing an electroplating processing line on the ground floor of Building 2. The shop operated from 1959 until 1992 and has been disassembled and removed from site. When in operation, three rooms housed the common metal plating operations for small parts. The fourth room housed the common metal cleaning and chrome irradiation lines for large work pieces and a wastewater neutralization process. The shop was reportedly underlain by a concrete floor and surrounded by a 6-inch-high concrete containment dike.

Spent corrosive solutions were reportedly processed through the neutralization tanks and then discharged to the sanitary sewer system. Wastewater generated after rinsing through the cold water tanks was reportedly also discharged directly to the sanitary sewer system.

The electroplating equipment has been removed from the former plating shop. Reportedly, the tank contents and the tank were disposed of, and all equipment was decontaminated and disposed of offsite, including the flooring.

SWMU 12 was investigated during the Facility Assessment. The Facility Assessment Report noted that site risks were below the target risk for industrial workers and within the acceptable target risk range for potential residents and recommended SWMU 12 for no further action.

Operable Unit 1 (OU-1): Groundwater at Building 36

Groundwater at SWMUs 26 through 30 were consolidated into OU-1 during the RCRA Facility Investigation based on physical proximity and similarities in site use resulting in potential petroleum-related releases to the environment. Prior to the RCRA Facility Investigation, SWMUs 26 through 30 were investigated separately. OU-1 is located around Buildings 32, 36, and 49, which is referred to as the Motor Pool Area located in the east-central portion of the facility.

SWMU 26: Building 36 Fuel Leaking Underground Storage Tanks (LUSTs) - The motor pool formerly operated five steel USTs: two 4,000-gallon gasoline USTs in the parking area south of Building 36, and one 1,000-gallon and two 500-gallon diesel USTs in the grassy area southeast of Building 36. In December 1992, the five LUSTs were excavated and removed from the site. During excavation activities, approximately 400 to 600 cubic yards of contaminated soil were removed. The tanks were replaced in January 1993 with two double-walled, 4,000-gallon gasoline USTs and one double-walled 2,000-gallon diesel UST that were equipped with an automatic leak detection system.

Follow-on investigations were coordinated through the D.C. Department of the Environment UST Division throughout the 1990s. A Case Closure determination (LUST Case Number 93-027) indicating that the old LUST site (SWMU 26) does not pose a threat to human health and the environment was provided by the D.C. Department of the Environment.

In the 2010, groundwater sampling conducted during the Facility Assessment detected benzene in two monitoring wells. This initiated a vapor intrusion investigation in the area of Buildings 32, 36, and 49 during the Phase II Facility Assessment. The Phase II Facility Assessment Report concluded that no further evaluation of vapor intrusion in Buildings 32, 36, and 49 Area was warranted.

SWMU 27: Building 36 Used Oil UST – Building 36 also reportedly operated a UST that stored waste oils generated from the Electrical Trades Branch (with the exception of transformer oils), along with other waste oils generated on the NRL. The size and location of the UST is unknown and the unit reportedly operated between 1971 and 1979. Waste oils were reportedly removed from the tank in 1979 for offsite refining and disposal by a contractor and the tank was reportedly removed in 1992.

SWMU 28: Building 36 Parts Washer – SWMU 28 was a parts washer located inside Building 36 and operated from 1984 until 2006. It consisted of a metal sink approximately 3-foot-long by 2-foot-wide by 1-foot-high, sitting on top of a 55-gallon steel drum in the north corner of the Building 36 garage. The drum, which held spent solvent, sat on a wooden pallet on an intact, epoxy-coated concrete floor in the building. No known releases have been reported from this SWMU.

SWMU 29: Building 36 Used Oil Area – The Building 36 Used Oil Area is located inside Building 36 and consists of two 275-gallon steel tanks. The tanks began operation in the 1970s and are still used. Both tanks sit in metal pans within a 3-foot-high concrete berm. Waste oil from garage operations is consolidated into 5-gallon cans. When the cans are full, they are emptied into the waste oil tanks located within the berm. Prior to 1979, waste oils reportedly were placed into SWMU 27 prior to offsite disposal. After 1979 and until 1991, wastes were transported to the Building 149 boilers for burning. No known releases have been reported from this SWMU.

SWMU 30: Building 36 Oil/Water Separator – The Building 36 Oil/Water Separator was located underground at the northwest side of the site, between Building 36 and Building 49. The unit managed oily wastewater from vehicle maintenance operations from 1975 until 2010. Oil from the oil/water separator was reportedly drummed and sent to Building 708T Oily Waste Storage for storage. Hazardous waste oil went to Building 82 Permitted Hazardous Waste Storage for storage prior to offsite disposal. The oil/water separator, co-located UST, and associated piping were removed in 2010. The tank removal report indicated that the tank was in good condition and that the soils around the tank exhibited no staining or odor. Confirmation soil samples were collected during the tank removal and the results were below the D.C. Department of Energy and Environment (previously known as the Department of the Environment) UST Program’s Soil Quality Cleanup Standards. Therefore, based on the results of the Phase 2 Facility Assessment and the subsequent removal action, no further action was recommended for SWMU 30.

In September 2017, USEPA issued a Final Decision and Response to Comments to the NRL which provided a determination of Corrective Action Complete without Controls for soils at SWMUs 26 through 30. USEPA’s determination also required further investigation for groundwater. In July 2019, the NRL was issued a RCRA Corrective Action Permit that required the NRL to conduct a RCRA Facility Investigation for groundwater at these sites. The Navy is currently conducting the RCRA Facility Investigation.

SWMU 42: Groundwater at Substation A

SWMU 42 is an approximately 25-square-foot concrete pavement outside storage yard located on the west side of the railroad spur. The storage yard began operation in the 1950s. Prior to 1975, the site was used to store polychlorinated biphenyl (PCB) waste. Waste transformer oils from the Electrical Trades Branch Transformer Servicing Operations in Building 2A Former Oil House (SWMU 4) were sent here for temporary storage prior to offsite disposal to the Defense Property Disposal Office (DPDO) in Brandywine, Maryland. After 1975, only drums of PCB-contaminated wastes (e.g., rags, absorbents, and Tyveks) were temporarily stored in the unit and subsequently sent offsite to the DPDO for disposal. After 1979, DPDO would no longer accept PCB-contaminated wastes and these wastes were then accumulated and stored pending arrangements for offsite disposal. The site ceased operation for PCB storage in 1980 and became an area for non-PCB electrical equipment storage. The last transformer was reportedly removed in 1992. This site is currently used for electrical equipment storage.

Soil at SWMU 42 was investigated for PCB contamination during the Facility Assessment and the Phase II Facility Assessment. The results of the first Facility Assessment recommended additional soil and concrete sampling to define the extent of PCBs. Based on the results of additional sampling conducted during the Phase II Facility Assessment, no further action was recommended.

Building 53 Area

The Building 53 area is located in a narrow alley between Building 53 and Building 93. Building 53 is a two-story cinder block building that houses a research laboratory and office space. Areas of the building immediately adjacent to the narrow alley are used as office space and as an electronics laboratory, and are occupied during a typical work week. Building 93 consists mostly of storage and warehouse space. Areas of Building 93 immediately adjacent to the narrow alley are used for storage, and consist of open-air, roofed storage areas and large, sheet-metal sheds with open bay doors.

As part of the 2008 Facility Assessment for groundwater, monitoring well NRB053-MW01 was sampled. Trichloroethene (TCE) was detected at a concentration of 67 micrograms per liter (μg/L), as well as other trace levels of other volatile organic compounds. During the Phase II Facility Assessment, the monitoring well was re-sampled in March 2010 and TCE was detected at a concentration of 81 μg/L. A vapor intrusion investigation was conducted for Building 53 and Building 93. Based on the results from this investigation, no further evaluation of vapor intrusion for the Building 53 Area was warranted. However, because of TCE concentrations exceeding regulatory criteria, the Building 53 Area was included in the RCRA Facility Investigation.

Building 71 Area

Building 71 occupies approximately 84,000 square feet and is constructed of cinder block masonry with ceilings 30 to 40 feet high. The building appears to be mainly slab-on-grade construction with the slab ranging in thickness from approximately 10 to 12 inches. Building 71 houses a number of different tenants who primarily perform research activities within compartmentalized laboratories, offices, or machine shop space.

The western two-thirds of the building contains various spaces occupied mostly by activities that require machine shop type operations. The eastern third of the building houses an optics research facility and temporary office spaces. No potential sources or releases to the environment are known to have occurred near the southeast corner of Building 71.

Monitoring well NRB071-MW06 was installed as part of the facility-wide hydrogeologic investigation and TCE was detected at a concentration of 29 μg/L, and TCE daughter products (other chemicals produced by the breakdown of TCE) were also detected. A vapor intrusion investigation was conducted during the Phase II Facility Assessment. Based on results from the vapor intrusion investigation, no further evaluation of vapor intrusion for the Building 71 Area was warranted. However, because of TCE concentrations exceeding regulatory criteria, the Building 71 Area was included in the facility-wide groundwater RCRA Facility Investigation.

Closed Installation Restoration Program Sites

In September 2017, USEPA issued a Final Decision and Response to Comments outlining the Final Remedy for 48 SWMUs and 55 AOCs as Corrective Action Complete without Controls. In addition, five SWMUs were identified for Corrective Action Complete without Controls for soil and four SWMUs were identified for Corrective Action Complete with Controls. Additional information about these sites can be found in the Final Decisions and Response to Comments, as well as the Administrative Record.

Munitions Response Program Sites

AOC 4: Bomb Testing Butt (UXO 1)

The Bomb Testing Butt occupied approximately 0.36 acre near the western boundary of the NRL, adjacent to the Potomac River and northeast of the pier. The Bomb Testing Butt appears on historical maps from approximately 1928 to 1940. It was most likely used for testing and mixing explosives and flammable chemicals used for torpedo propulsion experiments that were taking place at NRL at the time. Since the area is believed to have been used for testing and mixing explosives, no munitions of explosive concern are anticipated at the site.

The Bomb Testing Butt location is currently a developed area of the installation and is covered by a paved parking lot, as well as Building 43A. The site was investigated during the Munitions Response Site Inspection. Soil and groundwater samples were collected and analyzed for munitions constituents. Based on the finding of the Site Inspection Report, munitions constituents was not detected in site media at concentrations exceeding the project action levels and the site was recommended for no further action.

AOC 22: Original Explosion Pit

The Original Explosion Pit, which occupied approximately 218 square feet, was located in the north-central portion of the NRL, just south of Oberlin Avenue and adjacent to Building 57. The Original Explosion Pit was constructed between 1935 and 1936. Because of the proximity of buildings, it is assumed that activities at the Original Explosion Pit were not explosive in nature. The site was likely used for testing and mixing explosives and flammable chemicals after the Bomb Testing Butt was demolished in the late 1930s. The Original Explosion Pit is shown on maps of the installation until 1945; however, it is unlikely that the site was in use from 1943 to 1945. Since the area is believed to have been used for mixing and testing explosives, munitions of explosive concern are not anticipated at the site. According to as built drawings, the Original Explosion Pit has been redeveloped and sits within the footprint of Building 76.

The Original Explosion Pit was investigated during the Munitions Response Site Inspection. Soil samples were collected and analyzed for munitions constituents . Groundwater was not encountered within a depth of 10 feet below ground surface and therefore was not sampled. Based on the finding of the Site Inspection Report, munitions constituents were not detected in site media at concentrations exceeding the project action levels and the site was recommended for no further action.

AOC 25: Fire Pit (UXO 3)

The Fire Pit, which occupied approximately 1742 square feet, was located in the northwest corner of NRL, and was bounded to the north by Bolling Air Force Base and to the west by the Potomac River. Dredge spoils from the Potomac River were used to fill the area behind the seawall and create the land on which the Fire Pit was constructed. The Fire Pit was constructed between 1945 and 1946, and was operated as an open burn site until 1960. Historical documents report the burning of several types of explosives at the Fire Pit, including black powder, trinitrotoluene (TNT), tetryl, lead azide, and fulminate of mercury. Inert mortars found during utility construction for a nearby building suggest that munitions of explosive concern may be present in the Fire Pit area.

The Fire Pit is currently a developed area. The majority of the site is covered by a paved roadway, while the remainder is urban landscape (grass with a few trees). The site was investigated during the Munitions Response Site Inspection and the Supplemental Site Inspection. During the Site Inspection, soil and groundwater samples were collected and analyzed for munitions constituents. Based on the findings of the Site Inspection Report, munitions constituents was not detected in groundwater at concentrations exceeding the project action levels and no further action was recommended for groundwater. A localized area of lead detected in soil during the Site Inspection resulted in additional soil sampling during the Supplemental Site Inspection. Based on the results of this Supplemental Site Inspection, industrial land use was found to be acceptable and it was recommended that land use controls be implemented to prohibit any future residential use of the site.

AOC 26: Pistol Range (UXO 5)

The Pistol Range was located approximately 75 feet east of the Potomac River on the northwestern portion of NRL and included approximately 0.36 acre of land on the installation, 43 acres of land off the installation, and 121 acres over water. These acreages include the firing range and berm, located on the installation, and the downrange safety danger zone where errant shots may have traveled. In 1940, a seawall was constructed along the Potomac River. Dredge spoils were then used to fill the area behind the seawall and create the land on which the Pistol Range was constructed. The Pistol Range was used for small arms training by USMC guards stationed at NRL and the Naval Gun Factory from approximately 1942 until 1962. Inert mortars found during utility construction for a nearby building suggest that munitions of explosive concern may be present in the Pistol Range area.

The portion of the Pistol Range located on NRL is currently a developed area covered by an asphalt parking lot and Building 259. Daingerfield Island Park and Washington Sailing Marina occupy 43 acres of land located off the installation . The site was investigated during the Munitions Response Site Inspection and the Supplemental Site Inspection . During the Site Inspection, soil and groundwater samples were collected and analyzed for munitions constituents. Based on the findings of the SI Report, munitions constituents was not detected in groundwater at concentrations exceeding the project action levels and no further action was recommended for groundwater. Arsenic was detected in soil samples at concentrations exceeding the project action limits during the Site Inspection, which resulted in additional soil sampling during the Supplemental Site Inspection. Based on the results of the Supplemental Site Inspection, no unacceptable human health risks were identified and no further action was recommended for the site.

AOC 31: Relocated Explosion Pit (UXO 2)

The Relocated Explosion Pit occupied approximately 218 square feet. It was located in the north central portion of NRL, adjacent to a set of north-south traversing railroad tracks between Oberlin and Cooley Avenues. The Relocated Explosion Pit was constructed to replace the Original Explosion Pit, which was located approximately 500 feet southwest of the replacement location. The Relocated Explosion Pit was constructed in 1944 and first appears on a 1946 historical map of the installation. Based on the review of historical maps, the Relocated Explosion Pit was operated in this location until 1951. It is assumed that activities were similar to those conducted at the Original Explosion Pit and, therefore likely consisted of testing and mixing explosives and flammable chemicals. Since the area is believed to have been used for mixing and testing explosives, munitions of explosive concern are not anticipated at the site.

The Relocated Explosion Pit is currently a developed area of the installation and is covered by urban landscaping. The site was investigated during the Munitions Response Site Inspection. Soil samples were collected and analyzed for munitions constituents. Groundwater was not encountered within 10 feet below ground surface and therefore was not sampled. Based on the finding of the Site Inspection Report, munitions constituents was not detected in site media at concentrations exceeding the project action levels and the site was recommended for no further action.

AOC 38: Incinerator (UXO 4)

The Incinerator comprised approximately 261 square feet and was located along the northern border of NRL, approximately 500 feet from the Potomac River shoreline. Based on a review of historical maps, the Incinerator was operated between 1938 and 1960. According to historical documents, detonators and assembled delay elements were destroyed at the site by placing them individually down a pipe into a closed furnace.

The Incinerator was identified in the Munitions Response Site Preliminary Assessment (PA); however, it was screened out of the PA because indoor sites have no mechanism for “release to the environment” and therefore are not considered. No source of munitions constituents or munitions of explosive concern exists at the site since the destruction of detonators and assembled delay elements occurred within an enclosed structure. Therefore, this site was not considered for further analysis.